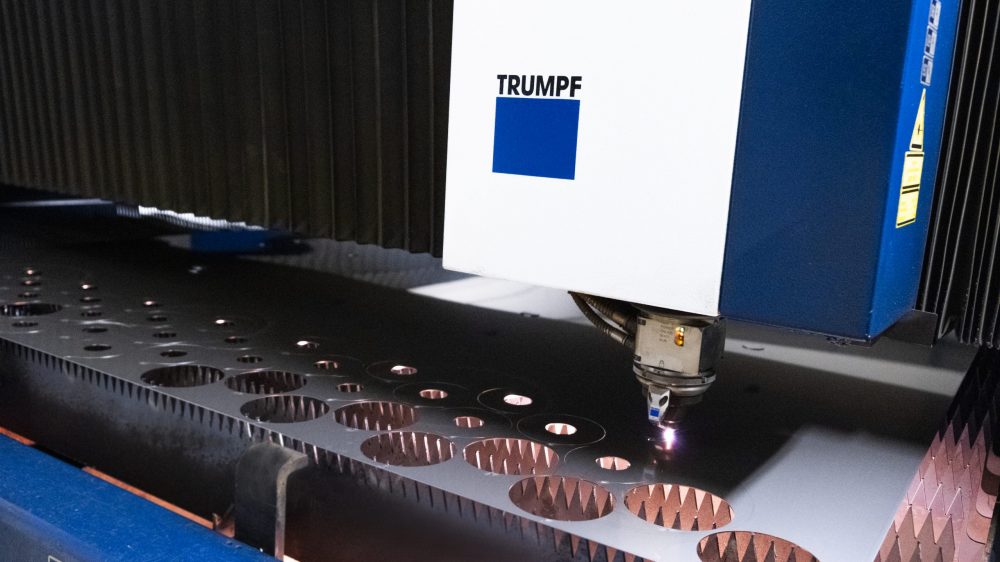

Laser Cutting

As a pioneer in metal processing sector, we are serving our clients on sheet metal laser cutting with leading TRUMPF machinery starting from 2004. Our machines with 1500×3000 mm and 2000×4000 mm capacities can process 0,5 – 20 mm stainless steel, ST 37 and aluminium and 0,5 – 8 mm copper, brass and titanium at high speed. No matter whether manufacturing low quantities or mass production, we are guaranteering ISO 9001:2015 quality level and the best raw material optimization, thanks to powerfull TRUMPF machinery.

The determining factor in quality and efficiency is the machine as a complete system of laser power and functions. That’s exactly why you can’t produce a good part without good technology, and we always adopt the principle of production with the best technology.

At the same time, with the automatic loading units we have, we can place the raw material in the machine without damaging the surface quality, and we can save a lot of time in this process compared to the traditional loading method.

Plasma & Oxy Cutting

Our machines with 2500×6000 mm and 2500×12000 mm capacities can cut 2 – 30 mm galvanized steel and ST 37 and 2 – 15 mm stainless steel. Also, they may process as inclined method for the sheets thicker than 10 mm.

With our plasma cutting machines that can cut up to 12 meters in length, high thickness materials can be processed with high precision. With this production method, which has high durability and low energy consumption, production can be made at low cost. With the oxygen cutting method, we can shape materials up to 200.00 mm in thickness with additional technologies such as microjoint at a speed of 15 meters per minute

Guillotine Cutting

Our machines that have maximum length of 3000, 4000 and 6000 mmcan cut 0,5 – 10 mm ST 37, ST 52, galvanized steel, aluminium, copper and brass.

Bending

Our press brake journey, which started in 1981, continues with our 8 press brake machines with different technology, tonnage and length. Different manufacturing and different thicknesses of sheet metal require varying amounts of force to bend. Tonnage is the measure of tons of force that a press brake machine can apply. Therefore, with our machines with different tonnage and length capacities, we are able to serve all demands from our customers within the framework of flexible production. While we provide low press costs with our hydraulic machines, we can achieve high speed and precision with our environmentalist values with our electrical machines. With our 50 years of press brake bending experience and our ever-renewing and developing mold library, we are able to both achieve small tolerances and provide the highest quality on the bending and bending surface.